Sorting returned and no longer used collected garments is a repetitive, strenuous and tiring task for workers. The introduction of a collaborative robot assistant (cobot), which combines image processing sensors, grippers and artificial intelligence, represents a viable alternative. It is also expected to have a positive impact on the distribution of second-hand items on the fashion market and the possibility of affordable business models with a limited environmental footprint.

CoboSort: recognising, gripping, discarding and learning

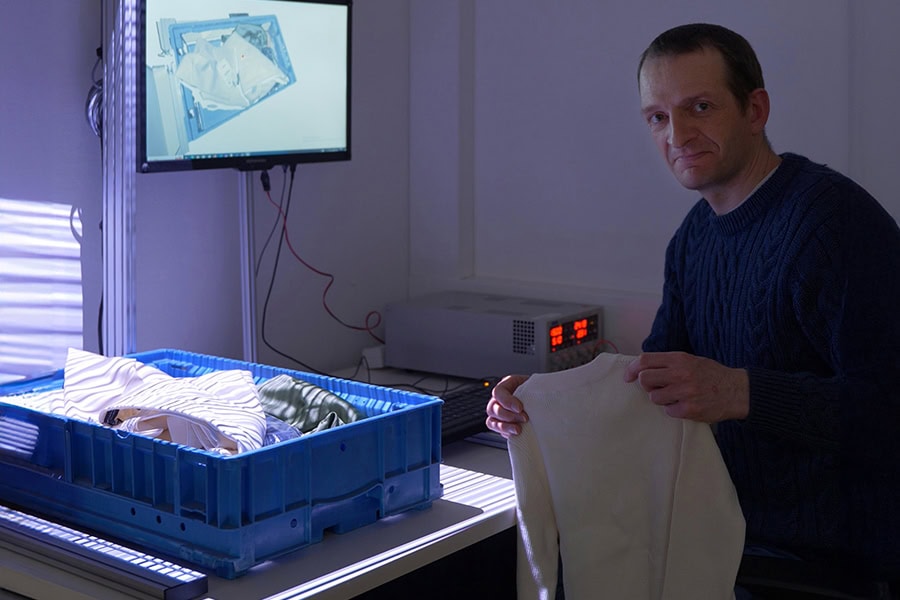

CoboSort focuses on the development of machine learning models and robotic grippers and their integration into a reliable and comprehensive collaborative robot system. This enables automated picking to support the sorting of fully, partially or unpacked garments. "This is becoming increasingly important in times of online retail, because returns are generated in large quantities and are often no longer properly packaged," reports Olaf Kähler from DIGITAL. An intelligent image recognition system including AI for recognition and a gripper system for gripping the garments work together. All of this takes place in an environment in which humans and robots work together directly. "Our institute's contribution is the software, the 'brain' so to speak, which tells the robot arm where to reach next," continues Kähler. "The difficulty here is that items of clothing are soft and - if they are not packed in a plastic bag like new items - cannot simply be gripped with a suction gripper. It is also important that garments are picked up individually and placed on the conveyor belt, as double gripping can lead to a backlog later on."

Environmentally friendly business models

The collaborative robot system sorts mixed and randomly arranged clothing packages, requires little space, is modular, safe and its functions can be reconfigured. Compared to current sorting solutions, it represents a moderate investment and paves the way for decentralised and flexible redistribution systems that support the emergence of new forms of e-commerce for unused or previously worn garments and recycling. By reducing the continuous production of new garments, the impact on the environment is also reduced.

Change in the fashion industry

This new approach enables synergies between fashion companies and end customers, reducing the production costs of garments and indirectly reducing raw material consumption and waste. Positive effects can also be expected in social terms: instead of performing repetitive, wear-and-tear activities, the labour force is given a proactive role. Using an intuitive interface that can also be operated by non-experts, they train the machine learning models and support the cobot in the event of an error. Major international fashion chains have already shown interest.

Partner:

UNIMORE – University of Modena and Reggio Emilia – Italien (Modena)

Mobile Biometrics – Spanien (Barcelona)

ShonMott – Spanien (Barcelona)

KattyFashion – Rumänien (Iași)

SIR – Italy (Modena)

CoboSort wird finanziert durch eit Manufacturing und die Europäische Union